Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 143

Decanter Centrifudge

Virtually all branches of industry need to separate solids from liquids at some point in their manufacturing processes. The decanter centrifuge is based on the simple idea of a clarifier or settling tank, in which particles, sediment and solids gradually fall to the bottom due to the force of gravity. However, such clarification is an extremely slow process and was not able to meet industry’s needs for more rapid, controllable results. The idea behind the development of the decanter centrifuge was therefore to provide the continuous mechanical separation of liquids from solids, to keep pace with modern industrial demands.

In essence, a decanter centrifuge is a clarifier whose base is wrapped around a center line. Rotating this unit rapidly means that the effect of gravity is replaced by a centrifugal force – the effect of which can be up to 4000 times greater. This force is then used to separate solids from liquids efficiently in a manner that is easy to control. Depending on the particular configuration and surrounding equipment, a decanter centrifuge can be used to separate a wide range of different solids from one or two liquid phases, on a continuous basis.

- DOWNLOADS

- ENQUIRE NOW

Working Principle

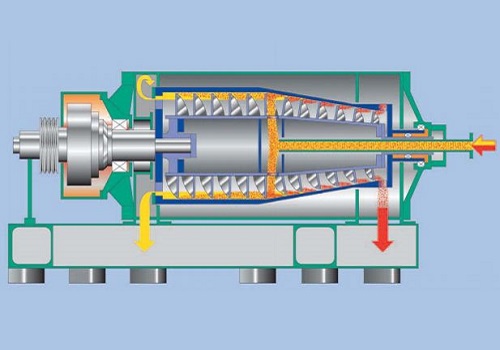

A decanter centrifuge separates solids from one or two liquid phases in one single continuous process. This is done using centrifugal forces that can be well beyond 3000 times greater than gravity. When subject to such forces, the denser solid particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer. The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually ploughed out of the liquid up the conical section. The centrifugal force compact the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl.

Application

Decanters are used in a wide range of industrial areas. Decanters are used in separation of liquid mixtures, separation of solid-liquid mixtures, dewatering, thickening, classification of solids and extraction of components.

Capacities

To suit application