Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

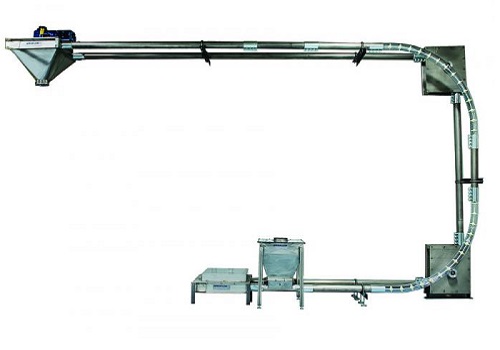

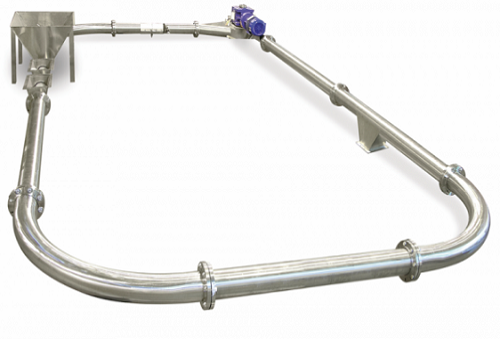

Tubo-Link Drag conveyors

JBM's tubo-link drag conveyor is the latest mechanical conveying option in our product line of mechanical conveyors designed for the dry bulk solids and powder processing industry.The hygienic, heavy duty, totally enclosed, dust-free tubular chain drag conveyor economically conveys dry, hot or cold, powders and granules, particularly fragile materials such as cereals, nuts, coffee beans, food ingredients, pet food, animal feed, and a wide variety of chemicals and plastics. Processors easily convey or batch ingredients with crevice free material contact surfaces with flexibility in layout options. They successfully convey any number of non-cohesive dry powders and granules from one point to other.

Tubo-link Drag Conveyors (TDCs) are mechanically driven conveyors that 'drag' material along the inside of a totally enclosed tube. They are designed to transfer a wide variety of bulk materials from a single or multiple in-feed points to a single or multiple discharge points through various configurations of totally enclosed tubing. TDCs use close-running discs connected by a cable or various styles of chain. They have been used successfully throughout a wide range of industries.

- DOWNLOADS

- ENQUIRE NOW

Working Principle

A continuous loop of cable or chain with discs spaced along its length is pulled by a motor driven sprocket within an enclosed tube. Changes in direction are facilitated by bends in the tubing or by corner housings with drive or idler sprockets for tighter radii. Discharge of the product is through either tube outlets or housing outlet boxes. Cable or chain and casing are routed back to the in-feed point in an endless loop.

Applications

Conveying of dry, hot or cold, powders and granules, particularly fragile materials such as cereals, nuts, coffee beans, food ingredients, pet food, animal feed, chemicals, detergents, latex, plastics, saw dust, wood chips and so on..

Capacities

There are many factors that enter into the tubular conveyor selection process such as material's bulk density, conveying rate, etc. Generally we can go for conveying capacities up to 10.5 m3 /hour.