Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 143

Pneumatic Conveyor

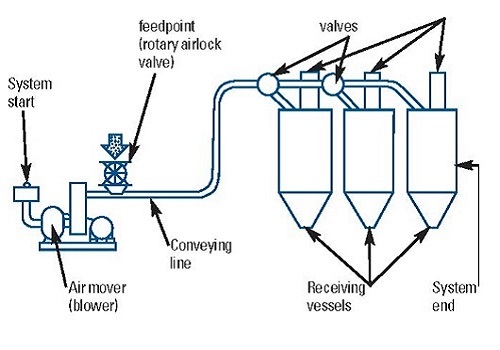

Pneumatic Conveying System is a widely adopted means of transporting dry bulk material either by Vacuum or by Pressure of Air. A pneumatic conveying system transfers powders, granules, and other dry bulk materials through an enclosed horizontal or vertical conveying line. The motive force for this transfer comes from a combination of pressure differential and the flow of air (or another gas) supplied by an air mover, such as a blower or fan. By controlling the pressure or vacuum and the airflow inside the conveying line, the system can successfully convey materials. Based on the product characteristics, conveying distance, and space available we can develop a conveying system best suiting your needs that gives you high efficiency, a dust-free closed operation that is dependable and gentle, and optimizes the use of space.

Pneumatic conveying provides several advantages over the mechanical conveying. A pneumatic conveying system can be configured with bends to fit around existing equipment, giving it more flexibility than a mechanical conveyor with its typically straight conveying path. This also means the pneumatic conveying systems occupy less space than a comparable mechanical conveyor. The pneumatic conveying system is totally enclosed, unlike many mechanical conveyors, which enables the pneumatic system to contain dust. The pneumatic conveying system typically has fewer moving parts to maintain than a mechanical conveyor, as well.

- DOWNLOADS

- ENQUIRE NOW

LeanO-Conveyor

The method of lean phase pneumatic conveying has been used from the beginning of pneumatic conveying. With lean phase conveying the ratio of conveying product to conveying air is low. In most cases the operating pressure of a lean phase conveying system is under one bar. When the product being conveyed can greatly vary in particle size, shape or bulk density, then lean phase may be the right choice.

Features:

- Low material to air ratios

- Works well in both vacuum and pressure conveying

Benefits:

- Conveys a very wide range of materials

- Well suited even if materials handled greatly vary in particle size, shape or bulk density

DenseO-conveyor

In dense phase conveying, particles aren’t suspended in the conveying air and are transported at high pressure and low velocity. Dense-phase pneumatic conveying is suitable for transporting a wide range of fine or coarse materials and uses positive pressure to push material along a pipeline in a plug form at low velocities. This results in significantly reduced pipe and component wear promoting minimum operational expenditure and extended life expectancy. Generally Dense-phase conveying is a preferred choice due to the low energy consumption, reliability and minimal operating costs. Application of Dense-phase pneumatic conveying is very extensive and requires vast knowledge of the materials to be handled and their key characteristics such as particle size, shape, bulk density and chemical composition.

Features:

- High pressure system conveying at between 3.0 – 4.0 bar.

- Different vessels to match a variety of applications.

Benefits:

- Highly efficient mode of pneumatic conveying.

- Low overall energy consumption.

- Low operational costs.

- Low velocity material transport along pipeline.

- Can be modified easily at a later stage to adapt to process / plant changes.

Capacities

Pneumatic conveying systems can be tailor made for use according to the respective bulk material, the nature of the task and the available space.