Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

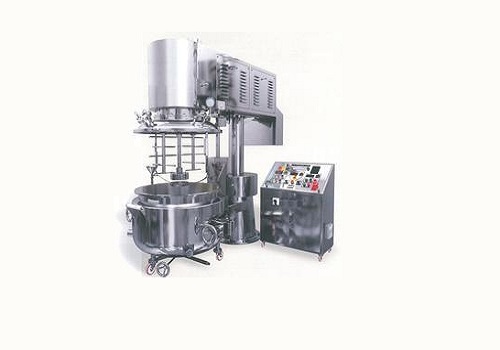

Planet Gear Mixer

The planetary mixer is so named because the mixing blade (commonly known as the beater) rotates in a planetary motion inside the mixer bowl. The beater has two types of movements: it revolves on it own vertical axis at high speed. At the same time, this vertical axis rotates around the center of the bowl at a relatively lower speed. The direction of rotation of the beater on its own axis and that around the axis of the bowl is in opposite directions.

The planetary motion of the beater is very effective in mixing the contents of the bowl. There are virtually no dead spaces in the mixing bowl. Scrapers with Teflon edges may be provided to wipe any material which may stick onto the internal surface of the bowl. Single planetary mixers are relatively inexpensive, versatile, and can be constructed in a range of sizes. The popular features of this mixer are the possible use of multiple bowls and beater designs with the same mixer assembly. The removable bowl design permits the mixing of one lot after another with minimum loss of production. While one bowl is attached to the mixer (in operation), the other can be loaded with material and made ready for mixing the next batch. In addition, a selection of beater designs is available and can be fitted depending on the product to be mixed.

- DOWNLOADS

- ENQUIRE NOW

Working principle

Planetary mixers consist of a single or double blade with a high speed dispersion blade. Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. The PGM consists of two open beaters moving in planetary motion, scraper blade & centrally located high speed homogenizer run by a separate motor to manufacture ointments. creams. suspensions etc.

Applications

Suitable for dispersing and mixing materials in industries such as coating, putties, adhesives, energy, pharmaceuticals, cosmetics, foods, etc

Capacities

50 liters to 1000 liters