Notice: Undefined variable: kkg in /home2/jbmpr32v/public_html/product_deatils.php on line 122

Air Jet Mill

The Air jet mills (fluid energy mills) are widely used in the manufacture of drugs and pharmaceuticals, organic and inorganic Chemicals, agro chemicals, pigments, food colour synthetic dyes, minerals, herbicides and pesticides, thermoplastics and other like heat sensitive , corrosive and abrasive mateials. The air jet mill employs compressed air, gas or high pressure superheated steam to achieve size reduction. These mills have no moving parts , thereby eliminating contamination due to contact with external grinding media. No additional heat is generated in grinding making it the ideal process to grind heat sensitive and fragile materials.

- DOWNLOADS

- ENQUIRE NOW

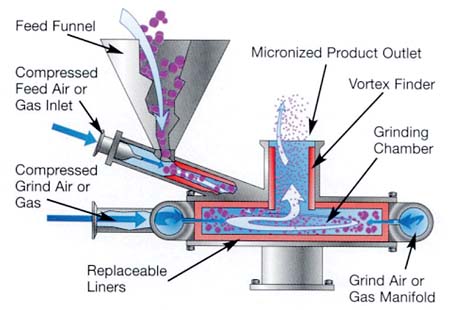

Working Principle

The Air jet mill works on fluid energy. Precisely aligned jets create a vortex inside the milling chamber. Material is fed into this vortex along an engineered tangent circle and accelerates at near super-sonic speeds. High-speed rotation subjects the material to particle-on-particle impact, creating increasingly smaller fines. While centrifugal force drives large particles toward the perimeter, fine particles move toward the center where they exit through the vortex finder.

Applications

The Air jet mill has been rigorously tested for complete scale-up from lab to production size with several sizes to choose from. It offers one-step grinding in a continuous or batch process with no dead zones to trap material, no moving parts to wear, no grinding media or lubrication to contaminate milled products. It is used in pharmaceutical, chemical, cosmetics, pigment, and ceramics industries, and can be applied to most bulk powder processing applications where sub-micron particle size is required.

Capacities

Capacity of the air jet mill depends on a number of factors including particle size of feed and product, material characteristics, Air pressure and input feed size.